From transportation hubs to shopping malls and lobbies, display screens in public areas face relentless challenges. Dust, humidity, and careless guests can all damage the precious LEDs that compose the pixels of large LED displays. This is where Glue-on-Board (GOB) LED technology comes in, offering remarkable durability and performance. But what exactly is GOB LED, and how can it bring value to your next display project?

Keep reading to learn more about GOB technology or explore ViewSonic’s All-in-One LED displays using GOB technology.

Over the years, LED displays have advanced through innovations in LED packaging and protection. SMD (Surface Mounted Device) LEDs were initially popular for their brightness and design flexibility, but their low self-protection led to high maintenance costs. COB (Chip on Board) technology then emerged, offering improved durability and thermal efficiency, but at a significant cost.

Now, GOB technology takes these advancements a step further by adding a protective epoxy resin layer over the LEDs. This provides a balanced solution, enhancing durability without the high costs associated with COB. Despite being around for some time in the outdoor LED screen market, many still don’t know what really hides behind this surface treatment innovation.

What’s GOB LED Technology?

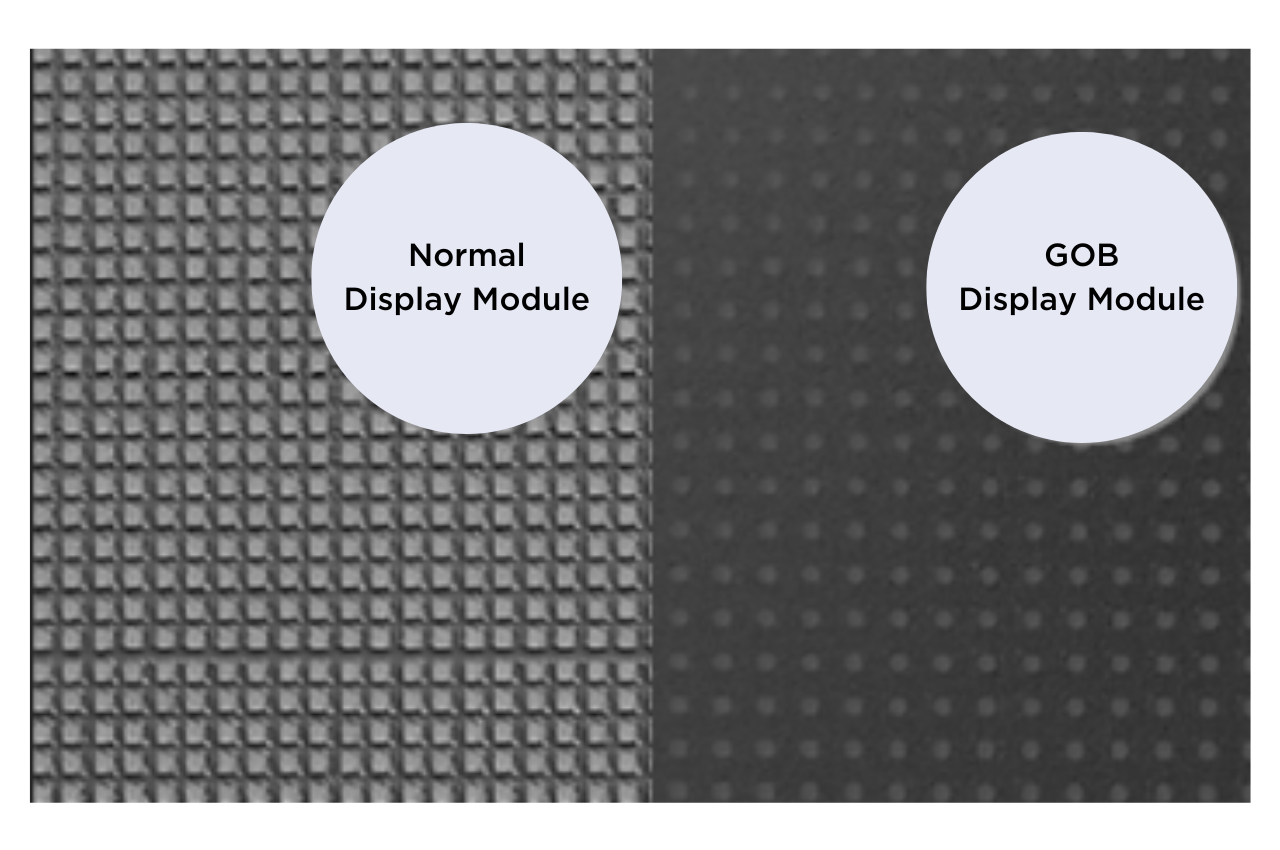

GOB (Glue on Board) LED technology involves the surface treatment of transparent epoxy resin over LED modules. Once the individual LED chips have been mounted onto the printed circuit board and packaged into an SMD module, the epoxy resin is evenly poured onto it to fill any gap between the top of the SMD LED and the base of the module.

This resin acts as a protective layer, safeguarding the LEDs beneath. But this protective layer is not just a shield; it plays an active role in maintaining the performance of the LED modules. The resin is applied with precision, ensuring that it does not interfere with the brightness and color accuracy of the display while also acting as an anti-glare coating.

Here’s how it works:

- Application: The epoxy resin is carefully applied over the LED module, creating a seamless and transparent layer.

- Protection: This layer protects against environmental elements such as moisture, dust, and physical impacts.

- Maintenance: The protective coating reduces the need for frequent cleaning and maintenance, as the LEDs are shielded from external contaminants.

But how does GOB LED compare to other LED technologies? Traditional SMD LEDs are left exposed after being packaged onto the modules, leaving them prone to damage from moisture, dust, and physical contact. While this might be acceptable in confined spaces or when displays are out of reach, it can be challenging in busier environments. As a result, individual LEDs or LED modules often require regular maintenance to ensure optimal performance.

Advantages of GOB LED Technology

Compared to more traditional LED technologies, GOB LEDs offer a set of distinct advantages. From enhanced durability to reduced maintenance and application flexibility, let’s review in detail how these benefits translate to real-life scenarios.

Durability Enhanced: Unmatched Longevity

One of the most significant advantages of GOB LED technology is its enhanced durability. The epoxy resin shield offers exceptional protection against environmental factors. Whether you’re setting up a commercial display in a high-traffic shopping mall or installing a public information screen in a bustling subway station, GOB LEDs can withstand various conditions, ensuring a longer lifespan and thus more consistent visual performance compared to traditional LED technologies, reducing maintenance costs and downtime.

Minimal Maintenance: A Cost-effective Solution

Maintenance can be a significant expense for large-format displays, as traditional LEDs often require regular maintenance to ensure optimal performance. GOB LEDs, however, minimize this need with their epoxy resin layer that acts as a self-protecting barrier, repelling dust and dirt. In special cases where cleaning is needed, the surface of GOB LED displays can be easily wiped with a regular rag.

This reduces maintenance frequency and operational costs, allowing your screens to focus on delivering stunning visuals. This benefit is further enhanced with an All-in-One LED Display, such as the ones provided by ViewSonic, whose modular design ensures full front-access maintenance capability, further streamlining maintenance and enabling quick and easy replacement of individual modules using an intuitive tool.

Real-life Applications: Where GOB LED Technology Excels

To truly appreciate the benefits of GOB LED technology, let’s explore some real-life applications. Consider the following scenarios:

Retail Environments

In a high-end retail store, maintaining an immaculate and engaging visual display is key to attracting customers. GOB LEDs provide vibrant and clear visuals while reducing the occurrence of dead pixels and constant maintenance. The durable epoxy layer ensures the screens remain pristine, even in a busy store with frequent customer interactions.

Transportation Hubs

Airports, train stations, and bus terminals are environments where screens are essential for providing information to travelers. These locations also pose unique challenges due to high foot traffic, varying environmental conditions, and the risk of physical damage. GOB LEDs, with their enhanced durability and minimal maintenance requirements, are the perfect solution. They can withstand the rigors of these settings while delivering reliable performance.

Corporate Offices

In modern corporate offices, digital displays are used for presentations, video conferencing, and information sharing. GOB LEDs offer the clarity and brightness needed for effective communication. Their minimal maintenance needs ensure a lower total ownership cost and mean that IT teams can focus on other critical tasks instead of constantly managing display upkeep.

Educational Institutions

Schools and universities are increasingly adopting video wall displays for interactive learning , assembly events, and information dissemination. GOB LEDs provide a durable and cost-effective option that can handle the daily wear and tear of educational environments. The protective resin layer ensures that screens remain functional and visually appealing, even with constant student use.

Final Thought

GOB LED technology represents a significant leap forward in the world of display technologies. By combining enhanced durability, minimal maintenance, and consistent visual performance, GOB LEDs offer a compelling solution for a wide range of environments. Whether you’re looking to upgrade your retail displays, enhance public information screens, or implement reliable digital signage in your office, GOB LEDs are a smart choice.

Ready to elevate your viewing experience? Explore ViewSonic’s All-in-One LED Displays using GOB technology here.

Was this article helpful?

YesNo